Stair Screen

reform, llc was commissioned to design and fabricate a new stair guardrail for a single-family residence in Arlington, VA. Rather that defaulting to the typical 3’-0” rail, we sought to provide an intervention that would utilize low cost, off-the-shelf products, transform them from ordinary, ignored materials into extraordinary, sculpted forms, reinforce existing spaces while resolving spatial disconnects and ultimately enhance the owner’s experience of moving vertically throughout the house.

The design utilizes the full height of the vertical stair opening between by inserting a light, screen-like element that spans from the stair treads to the upper level ceiling. In order to keep the screen lightweight and as visually transparent as possible, strips of poplar lattice trim are used. Since we could not rely on material bulk for the structural support, we recognized that the aggregate of lattice strips would need to produce the required structural rigidity. Furthermore, rather than understanding the flexible nature of the poplar strips (due to its length: cross section ratio) as a negative characteristic, we chose to use exploit it and use it as the basis of the structural form. The process that unfolded attempted to maximize the potential of the material’s bending capabilities to create a networked structural lattice while solving for the code requirements for the stair enclosure.

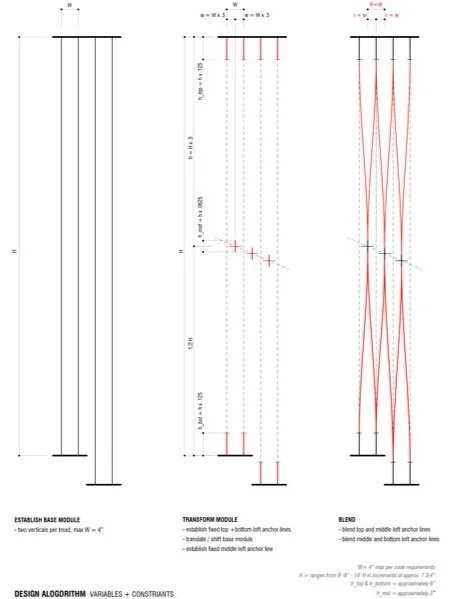

The development of the form began with several tests analyzing the bending limits over various lengths. A range of allowable height to width bending ratios were founds that allowed for allowable bending to occur at both the top and bottom of the stairs. The material data, coupled with building code requirements was inputted into a design algorithm that negotiated the relationships between the many dimensional variables and constraints of the site and structure. These initial screen patterns were evaluated and tested using full-scale mock ups. Various attachment / pinning methods capable of resisting the forces present in the screen were tested as well. Once finalized, each individual wood strip was virtually “unrolled” and the exact lengths and locations of holes for stainless steel spacer and bolts were tabulated into a spreadsheet. The data that was extracted from the virtual model was used to fabricate and assemble the screen by manually.

Ultimately, this logic-based, responsive form-making process resulted in a structure that performs on many levels. First, it performs structurally by resisting the forces imposed on it and preventing from someone falling into the opening. Secondly, it performs physically by creating a continuous, sculptural element between the upper and lower levels. Thirdly, it performs experientially by heightening one’s awareness of moving vertically in the house and lastly, it performs subconsciously by reminding one of the presence of the spaces above and below of where they are physically present.